COMMERCIAL Brass PLATING

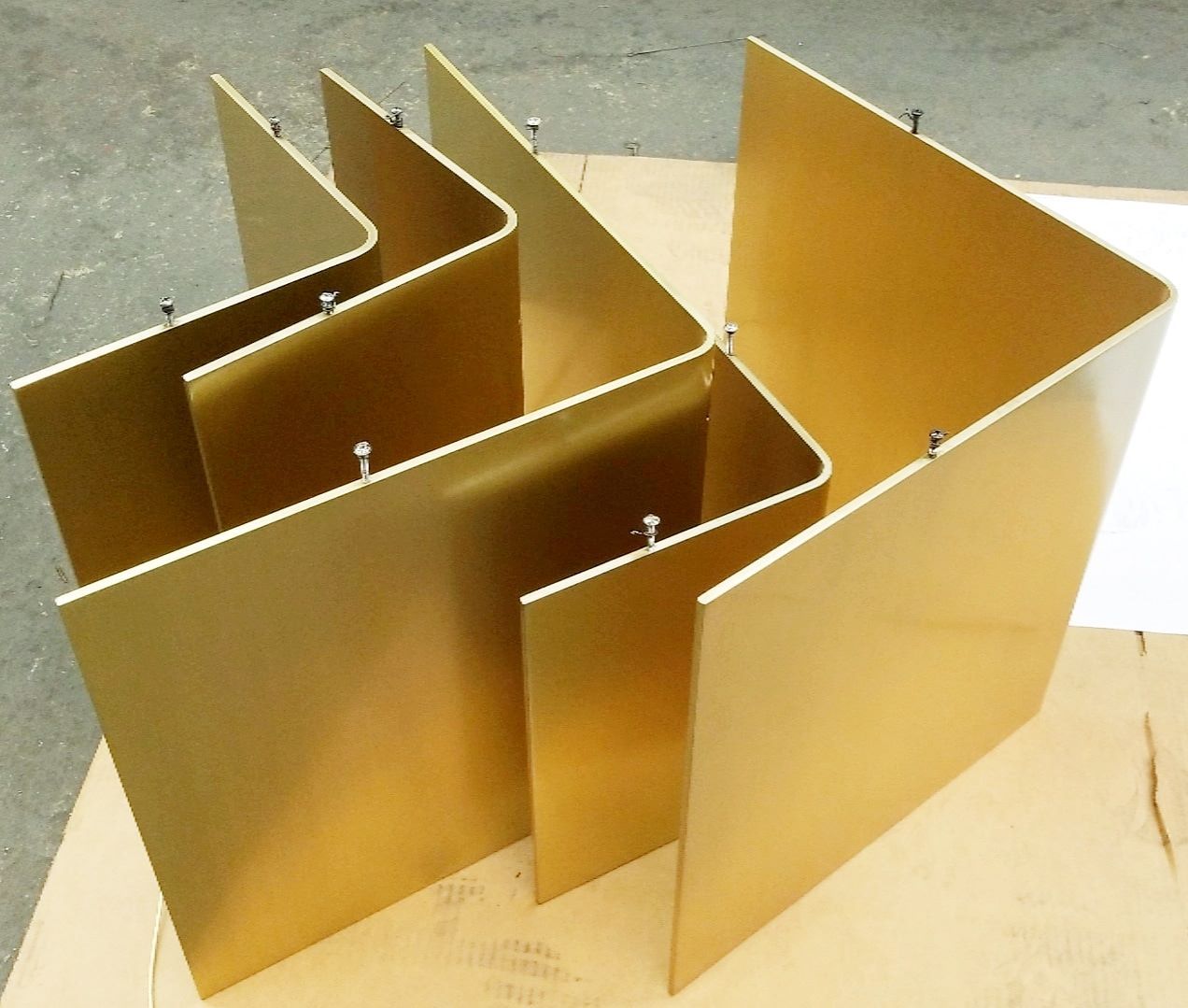

BRASS PLATING

Brass is an alloy of copper and zinc. Primarily, brass plating is used in decorative finishes. This plating, however, is also valuable in engineering uses. In the electrochemical process, a thin layer of brass is deposited on metal. Typically, this is used over a layer of nickel. To keep it from tarnishing, plated brass should always be coated with a lacquer.

Get A Quote

BENEFITS OF BRASS PLATING

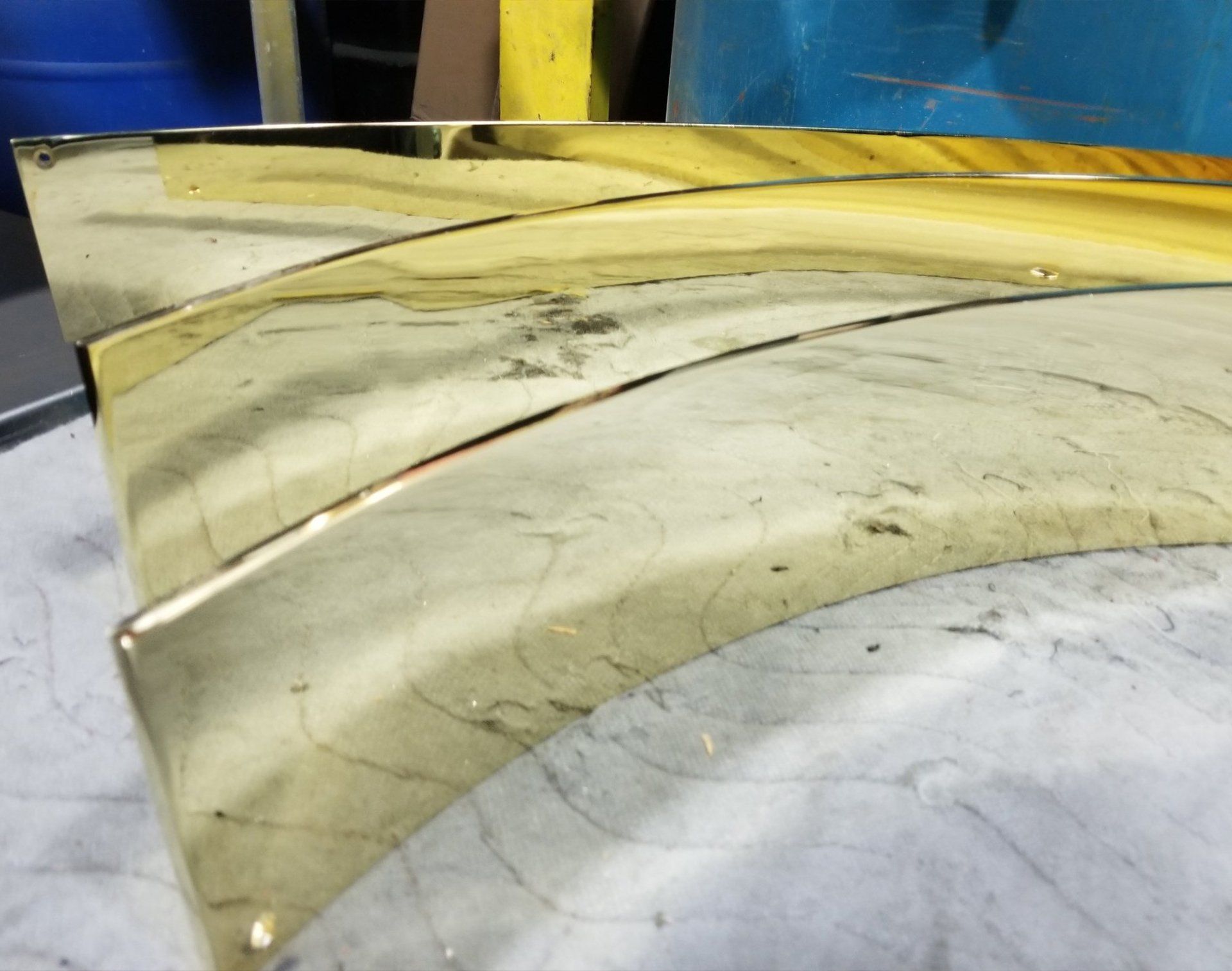

Brass plating is a cost-effective alternative to solid brass. It is offered in a variety of finishes to give you the appearance you are looking for. Brass plating is a great way to bring new finishes to older metal objects or to provide high-gloss finishes to sheets of fabricated metals. Though it is not as strong as other plating materials, brass works to enhance the look of electrical and display objects.

CARING FOR YOUR BRASS

Because brass is applied in such a thin layer, trying to polish your brass-plated item can easily remove the plating. This is also not an ideal finish for bathroom fixtures, as the lacquer will degrade with use, allowing your brass to tarnish. Lacquered items should only be cleaned with a damp, soft cloth. Small amounts of furniture wax can also be applied to help prolong the life of the lacquer.

FOREVER BRASS

Though it has a similar look to brass, Forever Brass is actually a Zirconium Nitride Physical Vapor Deposition (PVD). This coating is applied in a vacuum and is most commonly used on stainless steel and chrome plated surfaces. This coating is commonly found on newer plumbing fixtures since the lacquered coating is superior at resisting corrosion and tarnish.

About General Brite Plating

The brass plating is most effectively applied when done at temperatures of 95 to 105 degrees. This process normally takes place in tanks or barrels depending on the size of the item.

323-268-6353

323-268-6353

323-268-6353

323-268-6353